slurry recirculation pump

Applications of Drainage Pumps

In the ever-evolving landscape of architecture and construction, the significance of roof covering cannot be overstated. Whether it's a residential abode, a commercial edifice, or a sprawling industrial facility, the roof serves as the first line of defense against the elements. It not only protects the structure but also enhances its aesthetic appeal. This is where the expert craftsmanship of a roof covering manufacturer comes into play.

- Agricultural Use Farmers use these pumps to manage water levels in fields and to prevent flooding, ensuring optimal soil conditions for crops.

3, simple and easy to move, the weight of the drill machine is less than 500Kg, and can be broken down into three pieces, easy to move and put on the shelf.

3, simple and easy to move, the weight of the drill machine is less than 500Kg, and can be broken down into three pieces, easy to move and put on the shelf.

In general, increasing the concentration of HPMC will result in a higher viscosity In general, increasing the concentration of HPMC will result in a higher viscosity

In general, increasing the concentration of HPMC will result in a higher viscosity In general, increasing the concentration of HPMC will result in a higher viscosity

Its ability to form a gel when hydrated also makes it suitable as an excipient in oral and ocular formulations Its ability to form a gel when hydrated also makes it suitable as an excipient in oral and ocular formulations

Its ability to form a gel when hydrated also makes it suitable as an excipient in oral and ocular formulations Its ability to form a gel when hydrated also makes it suitable as an excipient in oral and ocular formulations

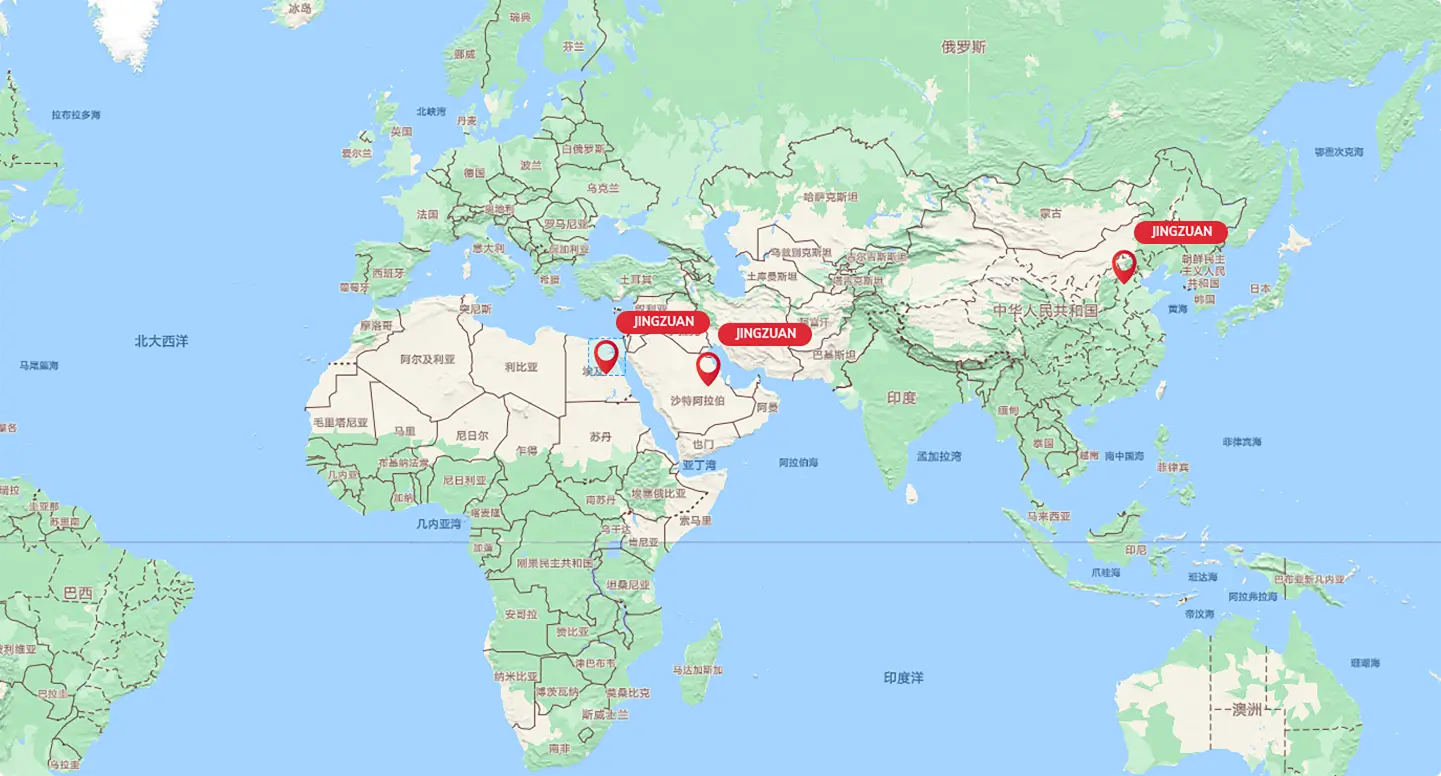

Chinese RDP products are exported globally, providing cost-effective solutions to construction industries worldwide Chinese RDP products are exported globally, providing cost-effective solutions to construction industries worldwide

Chinese RDP products are exported globally, providing cost-effective solutions to construction industries worldwide Chinese RDP products are exported globally, providing cost-effective solutions to construction industries worldwide