BS

Double Lips - * Industrial Machinery In industrial settings, the 35x47x7 oil seal is used in pumps, compressors, and other equipment to protect bearings and other critical components from contamination.

- By following these simple steps, you can replace your valve cover gasket and help ensure that your engine continues to run smoothly for many miles to come.

- There are many high pressure oil seals suppliers in the market, each offering a range of products with varying specifications and quality. When choosing a supplier, it is important to consider factors such as the reputation of the supplier, the quality of their products, and their customer service.

- Ultimately, the best type of spark plug for your vehicle will depend on your specific needs and budget. It's important to consult with a professional mechanic or automotive expert to determine the right spark plug for your engine. By selecting the right spark plug, you can ensure optimal engine performance, fuel efficiency, and reliability.

How Oil Seals

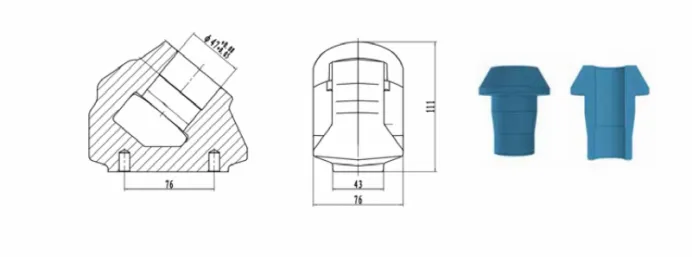

Figure 2.11. Rubber enclosed metal seal

Figure 4.6. Rubber reinforced with carbon black and CNT nanocomposite to reduce the accumulation of heat in tyre [42].

Overall, the Spark Plug 794 00082 is a top choice for drivers looking to improve the performance and efficiency of their vehicles. With its reliable ignition performance, enhanced fuel efficiency, and durable construction, this spark plug offers a range of benefits that can help you get the most out of your vehicle. Whether you're driving a compact car, a sports sedan, or a rugged truck, the Spark Plug 794 00082 is a smart investment that can help you enjoy a smoother and more efficient driving experience.

U-Shaped Silicone Gasket: Applications and Advantages

Smear a little gasket sealant round the cover flange and fit the new gasket to it. Make sure it is flat and straight.

synthetic rubber gasket.

• Super helix seal (seal with one-way two-step screw)

Most effective sealing is obtained with optimum shaft surface finishes. The sealing efficiency is affected by the direction of the finish tool marks and the spiral lead. Best sealing results are obtained with polished or ground shafts with concentric (no spiral lead) finish marks. If you must use shafts with spiral finish leads, they should lead toward the fluid when the shaft rotates.