Молотовая головка для дробления

Daily cleaning of the drilling rig is the foundation of maintenance work and the most important step. After each use, thoroughly clean the machine with compressed air or clean water, especially the radiator and air filter. This can prevent performance degradation due to overheating, as well as avoid faults caused by the accumulation of dust and mud.

Máy nén khí di động diesel mang lại nhiều lợi ích quan trọng, bao gồm

The production of rubber slurry pumps begins with the selection of high-quality materials. The primary components of these pumps include the pump casing, impeller, and wear components, all of which are crucial for efficient performance. Rubber, due to its excellent resilience and wear resistance, is widely used in constructing these components. Factories often source synthetic rubber, such as polyurethane, to enhance durability further, especially in harsh operating conditions.

2. Versatility These hammers can be used in various applications, including water well drilling, oil and gas exploration, and quarrying. The DTH technology can be adapted to different bit sizes and types, making it suitable for a wide range of geological conditions.

Self-priming slurry pump solutions are cutting-edge pumping systems designed to handle abrasive and viscous materials with ease. These pumps are equipped with unique priming capabilities that eliminate the need for external priming sources, making them ideal for applications where traditional pumps fall short.

Self-priming slurry pump solutions are cutting-edge pumping systems designed to handle abrasive and viscous materials with ease. These pumps are equipped with unique priming capabilities that eliminate the need for external priming sources, making them ideal for applications where traditional pumps fall short.

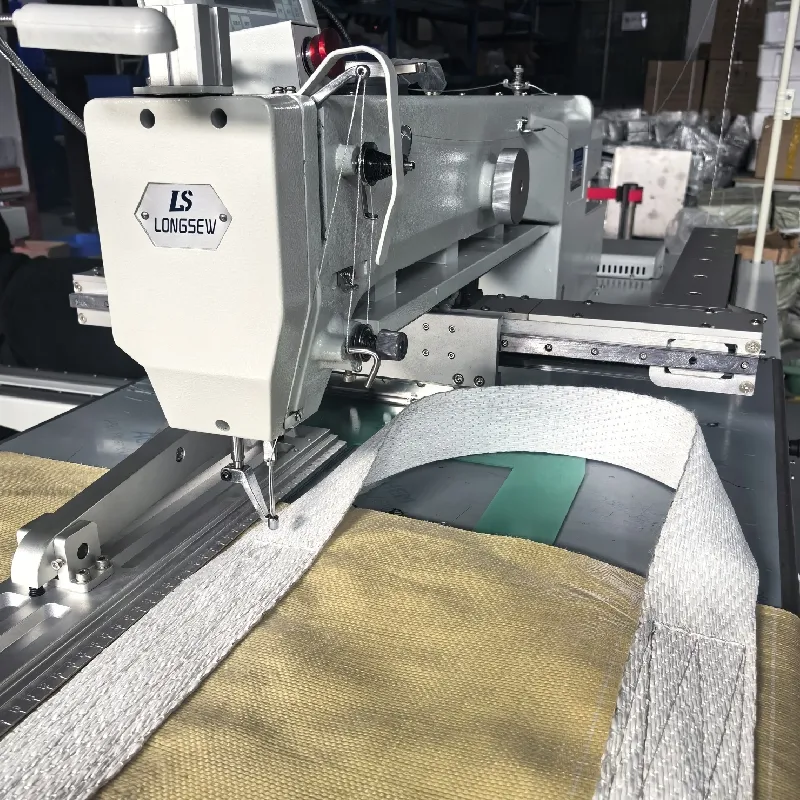

Arm sewing machines are also great for quick repairs or small sewing tasks, as they can easily be set up and put away when not in use Arm sewing machines are also great for quick repairs or small sewing tasks, as they can easily be set up and put away when not in use

Arm sewing machines are also great for quick repairs or small sewing tasks, as they can easily be set up and put away when not in use Arm sewing machines are also great for quick repairs or small sewing tasks, as they can easily be set up and put away when not in use