Drill pipes are essential for transmitting drilling fluids and rotational force from the surface to the drill bit. High-strength steel alloys are commonly used for drill pipes due to their ability to withstand high torque and pressure.

In the world of textile manufacturing, few innovations have had as profound an impact as the Union Lockstitch sewing method. This invention, which revolutionized the way fabrics are joined together, plays a critical role in various applications, from garment production to upholstery and beyond. The Union Lockstitch is a specific type of lockstitch created primarily for its durability, versatility, and efficiency.

Types of Heavy-Duty Thread

Conclusion

Understanding Pattern Sewing Machine Prices

3. Stitch Types and Length Different projects may require different stitch types. Make sure the machine allows you to customize stitch length to accommodate varying thicknesses and styles within your leatherwork.

- There are several types of seaming machines available, including lockstitch machines, overlock machines, and chain stitch machines. Each type has its own unique features and benefits, making them suitable for different types of projects. For example, lockstitch machines create a strong, straight seam that is suitable for most applications, while overlock machines are better for finishing edges and preventing fraying.

User-Friendly Design

Another notable benefit is the versatility that a walking foot provides. While it's especially known for its effectiveness with multiple layers and bulkier fabrics, this foot can also be advantageous for sewing straight lines and curves. Many modern sewing machines come with stitch settings compatible with the walking foot, allowing users to explore various sewing techniques. For example, one can easily create beautiful diagonal lines in quilting or sew intricate patterns that require precision.

4. Cost-Effectiveness The improved efficiency in filling and discharging operations due to spout rosettes can lead to significant cost savings. By optimizing material flow, companies can reduce the time needed for loading and unloading, leading to better utilization of labor and equipment.

3. Sewing Speed The speed of the sewing machine is an important factor, especially in a commercial setting. High-speed machines can significantly increase productivity, allowing more projects to be completed in a shorter amount of time.

3. Speed Using an overlock machine is typically faster than conventional sewing machines for finishing seams. For garment production, this speed can be an invaluable asset, enabling sewists to complete projects efficiently.

The Rise of Industrial Walking Foot Machines Revolutionizing Textile Production

In addition to its superior feeding mechanism, a compound feed heavy-duty sewing machine is also equipped with a powerful motor. This allows the machine to sew through multiple layers of fabric, thick materials, and heavy-duty materials with ease. The high-speed motor ensures fast and efficient sewing, making it ideal for large projects or production sewing.

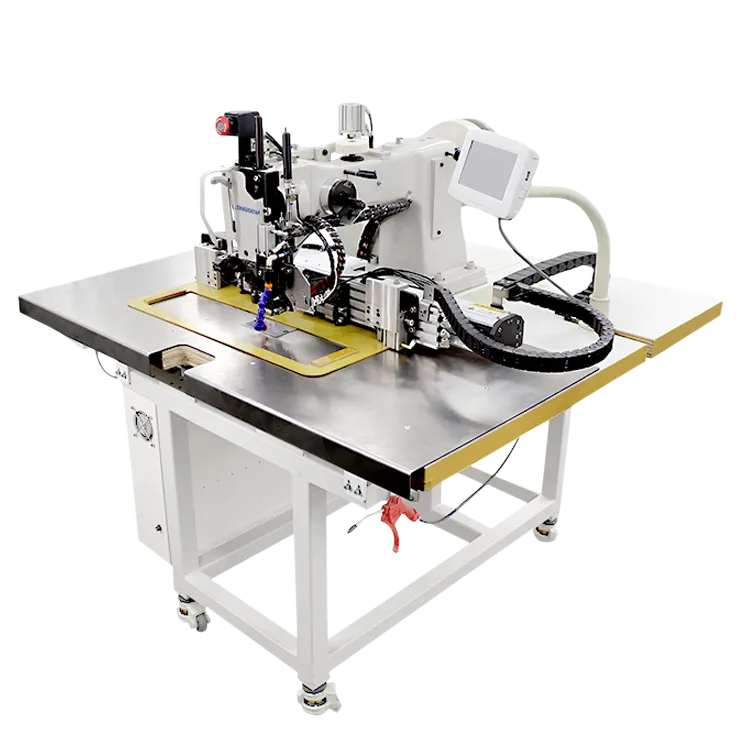

compound feed heavy duty sewing machine

How Much Space Do I Need For A Sewing Machine?

1. Efficiency A specialized sewing table streamlines your workflow, allowing you to transition seamlessly between cutting, sewing, and assembling pieces. This efficiency can save you time and reduce frustration.

2. Post-Bed Machines Designed for intricate work, post-bed machines offer excellent visibility and accessibility for detailed applications such as decorative stitching or repairs. The vertical post allows the operator to maneuver the leather easily, which is essential when working on items with complex shapes.

Conclusion

In conclusion, the role of industrial sewing machines in auto upholstery is crucial. These machines are not just tools; they are an integral part of the manufacturing process, directly impacting the quality and durability of vehicle interiors. As the automotive industry continues to evolve, the advancement in sewing technology will undoubtedly keep pace, providing upholstery professionals with the means to meet consumer expectations for quality and craftsmanship. Investing in high-quality industrial sewing machines can help manufacturers improve efficiency, enhance product offerings, and ultimately elevate the consumer's driving experience.

Upholstery is an art that blends creativity, design, and craftsmanship, allowing individuals to transform furniture pieces from ordinary to extraordinary. One of the essential tools for any upholsterer is the upholstery hand sewing machine. Unlike typical sewing machines, upholstery hand sewing machines are specially designed to handle heavy fabrics and materials that are commonly used in furniture upholstery, making them a vital addition to any craftsman's toolkit.

IV. Advanced Techniques and Tricks

The Artisan's Touch

5. Position the Bobbin Use the standard bobbin setup; the twin needle doesn't require a specific bobbin alteration. However, make sure the bobbin thread is appropriately wound and threaded through the machine.

In conclusion, an easy-to-use heavy-duty sewing machine is a must-have for anyone serious about sewing. Its durability, user-friendly features, and versatility make it a valuable tool for sewers of all levels. Whether you are a beginner looking to improve your skills or a seasoned pro tackling tough projects, investing in a high-quality sewing machine will make all the difference in your sewing experience.

Over the decades, automotive sewing machines have evolved dramatically, incorporating advanced technologies such as computerized controls and automated stitching systems. Modern machines are equipped with features that enable precise stitch formation, automatic thread trimming, and multi-directional sewing capabilities. This evolution has not only improved the speed and precision of the upholstery manufacturing process but also enhanced the overall quality of finished products.

2. Professional Quality The even and parallel lines of stitching produced by a double needle sewing machine enhance the overall appearance of finished projects. This is particularly important for commercial sewing, where the quality of the finish can impact sales and customer satisfaction.

To get the most out of sewing machine quilt patterns, mastering key techniques is vital. Here are a few essential tips

4. Quality of Stitches Industrial sewing machines offer superior stitch quality compared to home machines. The precision and consistency in stitching can elevate the overall quality of homemade products, making them look more professional. This advantage is particularly important for those who may want to sell their creations.

industrial sewing machine for home use

Moreover, the bobbin shuttle hook plays a vital role in the overall efficiency of the sewing process. In high-speed industrial settings, the speed at which a machine can operate is directly linked to the effectiveness of its components. A well-designed bobbin shuttle hook enables sewing machines to run at high speeds without compromising on stitch quality. This is particularly important in a fast-paced manufacturing environment, where time is money, and high-quality products are essential.

2. Cost-Effectiveness By utilizing high-quality stitching machines, manufacturers can achieve a higher production volume at lower operational costs. This translates to increased profitability and competitiveness in the market.