pompe centrifuge à entrée unique verticale

Advantages of Bullet Teeth

Seamless Integration

Seamless Integration

Conclusion

Advantages of Bullet Teeth

Types of Drilling Machines

Future Developments and Innovations

Exploring the CFM 185 Air Compressor A Comprehensive Overview

The main components of submarine hammer drilling equipment include the drill rig, hammer, drill pipes, and the drill bit. The drill rig is often mounted on a surface vessel or a floating platform and is designed to support the excessive weight and dynamic forces encountered during drilling operations.

Submarine hammer drilling, often referred to as underwater percussion drilling, is an advanced technique utilized primarily in marine construction and resource exploration. This method combines the principles of traditional drilling with hydraulic and pneumatic operations, enabling the effective penetration of hard substrates beneath the sea floor. In this article, we will explore the processes, equipment, advantages, and applications of submarine hammer drilling.

Heavy slurry pumps from China play a vital role in multiple industries, offering effective solutions for the transportation of complex materials. Their cost-effectiveness, technological advancements, and customization potential make them an attractive choice for businesses around the world. As with any procurement decision, careful consideration and planning are essential to harness the benefits while mitigating risks. The demand for heavy slurry pumps is likely to grow as global industries continue to expand, making it an area worth monitoring for future developments.

2. Correct Configuration Ensuring that the jaw plates are correctly aligned and configured can prevent unnecessary wear and improve the overall crushing performance.

New Bearing Technology Could Revolutionize Manufacturing Processes

They might be forced to pass on these increased expenses to their customers or look for alternative suppliers, which could compromise product quality or delay delivery schedules They might be forced to pass on these increased expenses to their customers or look for alternative suppliers, which could compromise product quality or delay delivery schedules

They might be forced to pass on these increased expenses to their customers or look for alternative suppliers, which could compromise product quality or delay delivery schedules They might be forced to pass on these increased expenses to their customers or look for alternative suppliers, which could compromise product quality or delay delivery schedules 22232 bearing price. Moreover, small and medium-sized enterprises (SMEs) that lack the bargaining power of larger corporations might find it difficult to absorb these additional costs, leading to reduced profit margins or even closures.

22232 bearing price. Moreover, small and medium-sized enterprises (SMEs) that lack the bargaining power of larger corporations might find it difficult to absorb these additional costs, leading to reduced profit margins or even closures.

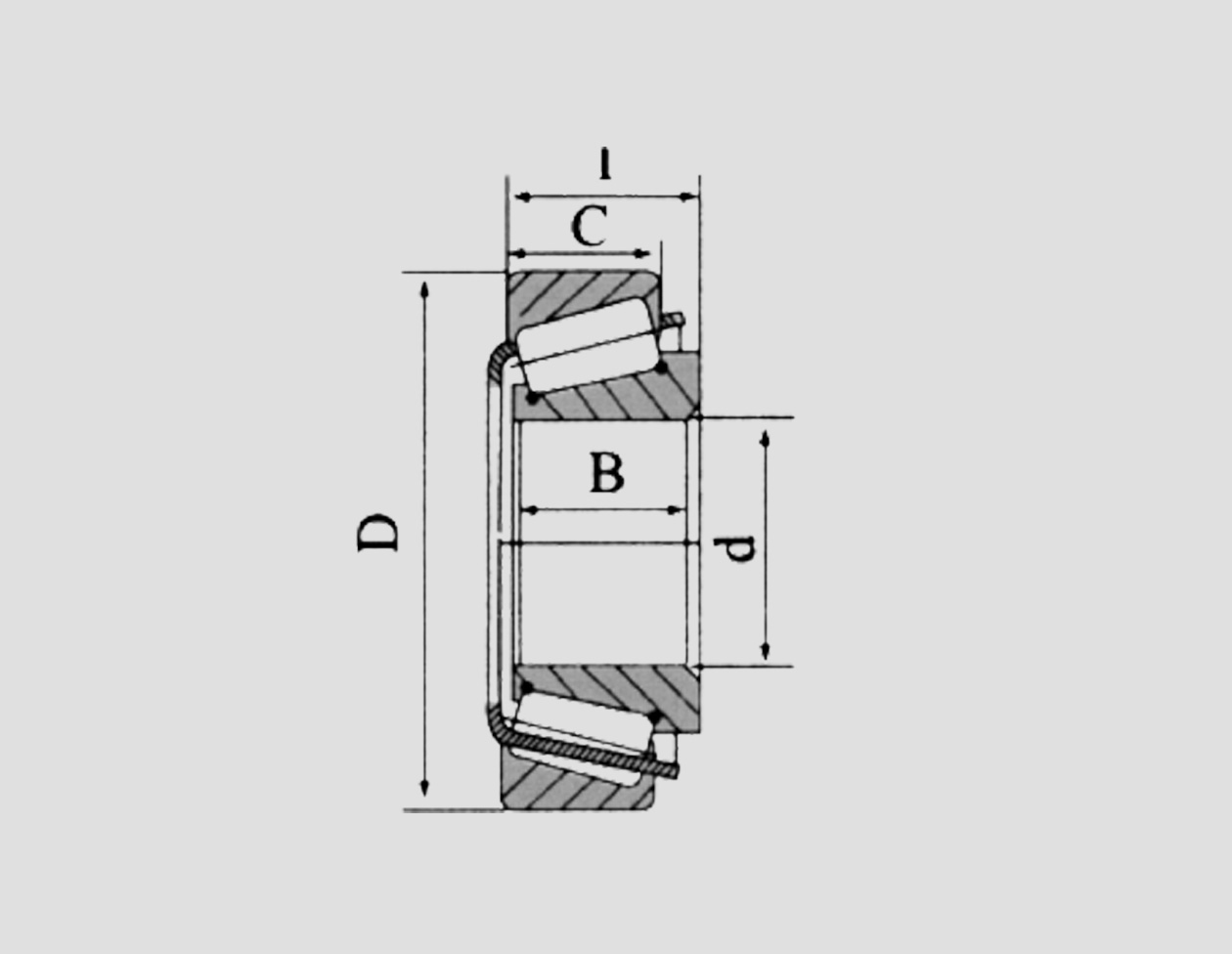

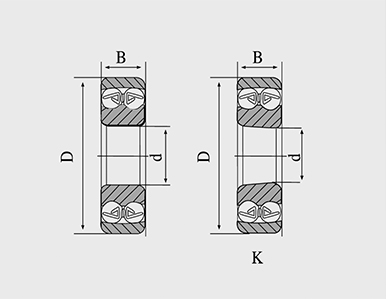

nu 316 bearing. Typically made from high-quality steel, these bearings are often heat treated for increased hardness and resistance to wear and tear. Some manufacturers also incorporate anti-corrosion treatments, enhancing their performance in harsh environments.

nu 316 bearing. Typically made from high-quality steel, these bearings are often heat treated for increased hardness and resistance to wear and tear. Some manufacturers also incorporate anti-corrosion treatments, enhancing their performance in harsh environments. lm67010 bearing. This means that it requires less energy to rotate, resulting in increased efficiency and reduced wear on the bearing itself. This is especially beneficial in applications where energy consumption is a critical factor, such as in wind turbines or other renewable energy systems.

lm67010 bearing. This means that it requires less energy to rotate, resulting in increased efficiency and reduced wear on the bearing itself. This is especially beneficial in applications where energy consumption is a critical factor, such as in wind turbines or other renewable energy systems.