3 4 perforación

The Mechanism Behind DTH Drilling

- Pressure Control Drilling fluids help balance the pressure exerted by subsurface formations, preventing blowouts.

Understanding Down the Hole Drilling Rigs An Essential Tool in Modern Mining and Construction

ความสำคัญของ CFM 185

The geographical location of purchase can also impact pricing. In areas with limited access to suppliers or higher shipping costs, drilling machines may be more expensive. Local taxes and tariffs can further increase the overall cost. Therefore, businesses must factor in these additional expenses when budgeting for new equipment.

In summary, choosing the right pump for slurry applications is crucial to ensure efficient operation and minimize operational costs. Centrifugal and positive displacement pumps each have their distinct advantages, depending on the specific needs of the slurry being handled. By considering the properties of the slurry, pump material, required flow rates, operating conditions, and maintenance needs, industries can optimize their slurry handling processes for better performance and longevity. Ultimately, the right pump selection can lead to increased productivity and reduced wear and tear in industrial operations.

(4) When replacing the drill bit, the drill bit should be gently pressed against the rock, so that the motor of the drill can be reversed to complete the sensitive unloading head.

Mud and sediment can pose severe threats to property. They can damage structural foundations, promote mold growth, and create unsanitary conditions. In agricultural and construction settings, mud buildup can disrupt operations and impede access to vital areas. Therefore, employing an effective system to evacuate mud is essential for maintaining integrity and safety.

Construction Sector

Construction Sector

The corresponding angle of twist is read off a calibrated scale on the wrench The corresponding angle of twist is read off a calibrated scale on the wrench

The corresponding angle of twist is read off a calibrated scale on the wrench The corresponding angle of twist is read off a calibrated scale on the wrench

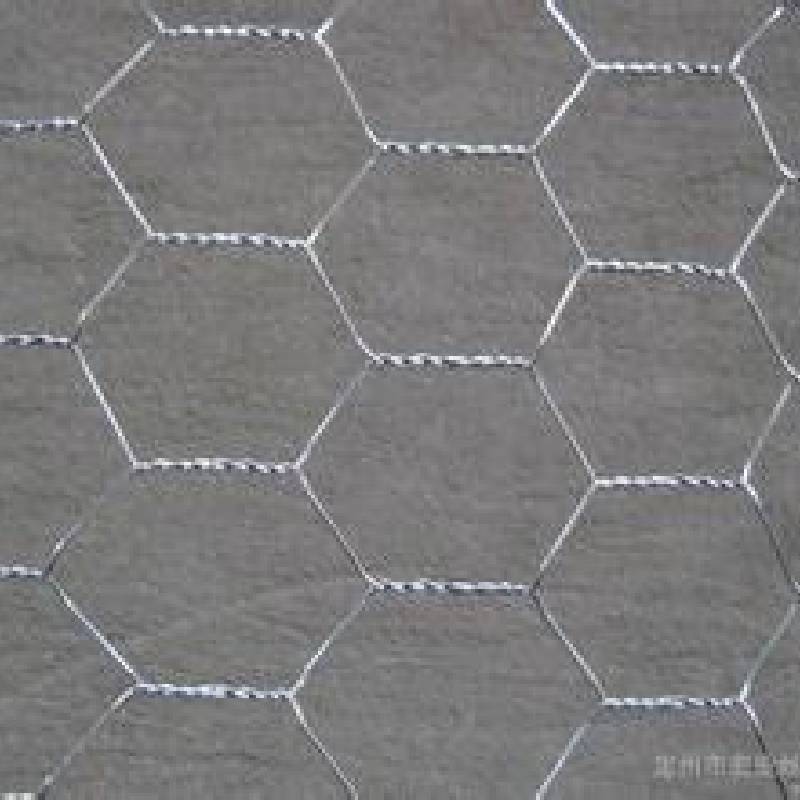

They come in a variety of heights and gauges, allowing property owners to choose the size and thickness that best suits their security needs They come in a variety of heights and gauges, allowing property owners to choose the size and thickness that best suits their security needs

They come in a variety of heights and gauges, allowing property owners to choose the size and thickness that best suits their security needs They come in a variety of heights and gauges, allowing property owners to choose the size and thickness that best suits their security needs

Most models come with pre-drilled holes and clear instruction manuals, enabling quick and easy setup by professionals or DIY enthusiasts alike Most models come with pre-drilled holes and clear instruction manuals, enabling quick and easy setup by professionals or DIY enthusiasts alike

Most models come with pre-drilled holes and clear instruction manuals, enabling quick and easy setup by professionals or DIY enthusiasts alike Most models come with pre-drilled holes and clear instruction manuals, enabling quick and easy setup by professionals or DIY enthusiasts alike