Manufacturing Sector

Manufacturing Sector

In summary, the 185 CFM portable air compressor is a multifaceted tool that meets the air supply needs of various industries. Its combination of power, portability, durability, and fuel efficiency makes it an outstanding choice for professionals who require reliable performance in demanding environments. As the industry continues to evolve, investing in a high-quality portable air compressor will undoubtedly enhance productivity and operational efficiency, proving essential for success in your endeavors. Whether you are a seasoned contractor or a DIY enthusiast, the 185 CFM portable air compressor is a worthwhile addition to your toolkit.

4. Reputation and Experience An established supplier with a proven track record in the industry can provide assurance regarding the quality and reliability of their products. Companies should look for suppliers with extensive experience in manufacturing mud pumps and a solid reputation among industry peers.

Conclusion

Understanding 185% Compressors The Key to Efficient Performance

The demand for 185 CFM air compressors continues to rise, driven by the relentless pace of industrial activities. As construction projects expand and the need for skilled labor increases, contractors are investing in high-quality equipment to ensure efficiency and reliability. Furthermore, the rise of DIY culture has also contributed to the growth of the market, as homeowners seek powerful tools for personal projects.

The Future of Portable Rotary Air Compressors

The versatility of 185 CFM air compressors makes them suitable for a wide range of applications. In the construction industry, these compressors are used to power tools such as jackhammers, nail guns, and drills. They provide the necessary pressure to perform tasks efficiently, which helps in accelerating project timelines.

Despite their crucial role, slurry pumps face several challenges. Abrasive materials can cause significant wear and tear, leading to frequent maintenance needs and potential downtime. This not only affects operational efficiency but can also lead to increased operational costs. Therefore, mining companies are continually seeking innovations in pump technology to enhance durability and efficiency.

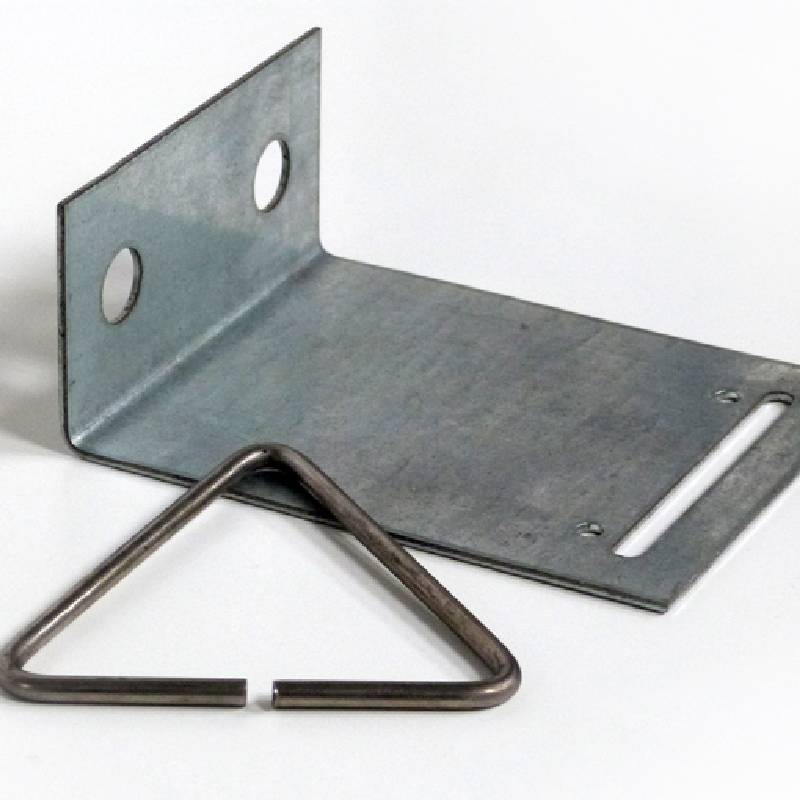

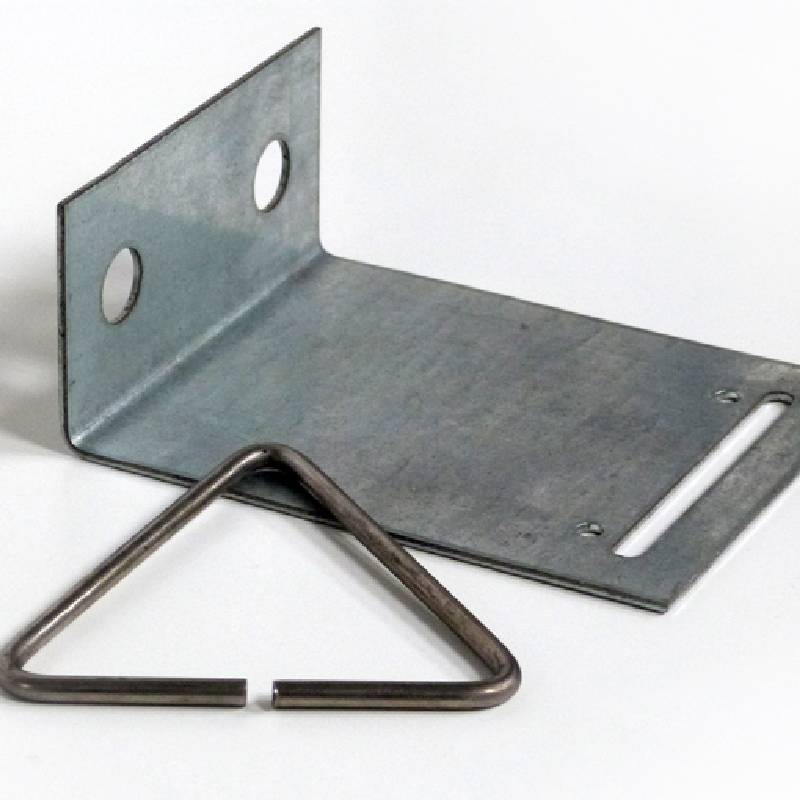

Steel bars, usually made from high-strength, corrosion-resistant materials, are placed within the bed joints during the masonry construction Steel bars, usually made from high-strength, corrosion-resistant materials, are placed within the bed joints during the masonry construction

Steel bars, usually made from high-strength, corrosion-resistant materials, are placed within the bed joints during the masonry construction Steel bars, usually made from high-strength, corrosion-resistant materials, are placed within the bed joints during the masonry construction joint reinforcement masonry. These bars, known as masonry ties, are designed to bond with the mortar and the masonry units, creating a cohesive structure. Alternatively, fibers can also be used, particularly in modern, more innovative construction methods, offering similar benefits with a different approach.

joint reinforcement masonry. These bars, known as masonry ties, are designed to bond with the mortar and the masonry units, creating a cohesive structure. Alternatively, fibers can also be used, particularly in modern, more innovative construction methods, offering similar benefits with a different approach.Concrete mesh also known as reinforcing mesh, is a grid of steel wires used to reinforce concrete in construction projects. This mesh enhances the tensile strength of concrete, preventing cracking and improving overall durability. Commonly used in slabs, walls, and foundations, concrete mesh ensures that structures can withstand various stresses and loads. Its application is essential in both residential and commercial building projects, providing long-lasting stability and safety.

Place the Cage Before planting your tomato seedlings, place the cage around the spot where you plan to plant them Place the Cage Before planting your tomato seedlings, place the cage around the spot where you plan to plant them

Place the Cage Before planting your tomato seedlings, place the cage around the spot where you plan to plant them Place the Cage Before planting your tomato seedlings, place the cage around the spot where you plan to plant them installing tomato cages. Make sure the cage is positioned securely in the ground to prevent it from tipping over once the plants start to grow.

installing tomato cages. Make sure the cage is positioned securely in the ground to prevent it from tipping over once the plants start to grow. 42 tomato cage. Made from high-quality materials, these cages are built to last. They can withstand harsh weather conditions and are resistant to rust and corrosion. This means that farmers can invest in these cages once and use them for multiple growing seasons, reducing their overall costs and increasing their profit margins.

42 tomato cage. Made from high-quality materials, these cages are built to last. They can withstand harsh weather conditions and are resistant to rust and corrosion. This means that farmers can invest in these cages once and use them for multiple growing seasons, reducing their overall costs and increasing their profit margins.

By locking up their cryptocurrencies in a smart contract, users can earn rewards in the form of newly minted coins or tokens without having to actively trade or invest By locking up their cryptocurrencies in a smart contract, users can earn rewards in the form of newly minted coins or tokens without having to actively trade or invest

By locking up their cryptocurrencies in a smart contract, users can earn rewards in the form of newly minted coins or tokens without having to actively trade or invest By locking up their cryptocurrencies in a smart contract, users can earn rewards in the form of newly minted coins or tokens without having to actively trade or invest metal stake. This makes metal staking an attractive option for those looking to generate passive income.

metal stake. This makes metal staking an attractive option for those looking to generate passive income.Beyond sculptures and jewelry, Galvanized iron wire is widely used in crafting decorative home items. Crafters create a variety of functional and ornamental pieces, such as wire baskets, picture frames, candle holders, and wall hangings. The wire's robustness ensures that these items are not only visually appealing but also practical and long-lasting. For instance, a wire basket made from galvanized iron can hold fruits or other household items without bending or breaking. Similarly, picture frames and candle holders crafted from this wire add a rustic charm to home decor while providing reliable functionality. The ease of working with galvanized iron wire allows DIY enthusiasts to customize their home items, making each piece unique.

Some of the key areas where these springs are used include

Some of the key areas where these springs are used includeFurthermore, HD coil springs are versatile and can be customized to suit the specific needs of a vehicle. Whether it's adjusting the spring rate to accommodate a particular load or fine-tuning the height of the vehicle for optimal performance, HD coil springs can be tailored to meet the requirements of different driving conditions.

Choosing reliable concrete accessories suppliers is essential for obtaining high-quality products that meet industry standards. Reputable suppliers provide a comprehensive range of accessories, from basic formwork components to advanced reinforcement materials. Partnering with trusted suppliers ensures access to durable, high-performance products that contribute to the success of construction projects. Reliable suppliers also offer expert advice and support, helping contractors select the right accessories for their specific needs, thus optimizing the construction process and ensuring safety and efficiency.

One of the primary uses of Galvanized iron wire in construction is for tying rebar, which forms the backbone of reinforced concrete structures. Rebars, or reinforcing bars, provide the tensile strength needed to support the concrete under various loads. Galvanized iron wire is used to tie these bars together at intersections, ensuring they stay in the correct position as concrete is poured and set. The wire's strength and resistance to corrosion ensure that the rebar remains securely tied even in the harshest of conditions, maintaining the structural integrity of the construction.