Construction Sector

Construction Sector

As a merit in the mining of rock, the drilling rig has to be mentioned. In addition, the drilling rig can also be used as a breaker to break up hard layers such as concrete. According to its power source, the rock drill can be divided into four categories: pneumatic rock drill, internal combustion rock drill, electric rock drill and digging and changing drill.

In conclusion, rubber-lined pumps are a crucial component in various industrial processes. Their robust design, versatility, and low maintenance requirements make them an attractive choice for industries that demand reliability and efficiency. As industries continue to evolve and face new challenges, the significance of rubber-lined pumps will undoubtedly grow, ensuring the safe and effective transfer of materials in an increasingly complex industrial landscape. Embracing this technology not only enhances operational efficiencies but also contributes to long-term sustainability goals in modern manufacturing and processing environments.

185% compressors come equipped with a variety of features that enhance their performance and usability. Typically, these compressors are powered by diesel engines, enabling them to operate efficiently even in remote locations where electricity is not readily available. Their compact size, combined with large pneumatic wheels, makes them easy to transport across construction sites.

Types of Drilling Machines

The DTH hammer operates through a system of compressed air. High-pressure air is directed down the drill string, powering the hammer at the end of the drill bit. The hammer strikes the bit with considerable force, fracturing the rock immediately beneath it. As the bit penetrates further, the broken rock is then cleared from the hole by the same air stream, allowing for continuous drilling without the interruptions often associated with other drilling methods.

The reason:

The suction pipe is not filled with water

Blocked suction line or inadequate valve opening

The inlet pipe of the pump, the meter or the stuffing box are serious

Benefits of Rubber Slurry Pumps

まず、le dhd380のなとして、そのいがげられます。このは、のテクノロジーをしてされており、やなデータをしています。これにより、のやのにしています。えば、においては、le dhd380をすることでラインのがられ、のやコストのがされています。

1. Increased Efficiency By providing a high volume of air, the CFM 185 enhances the efficiency of pneumatic tools, allowing for faster job completion.

Its open design facilitates air circulation and sunlight penetration while providing secure containment Its open design facilitates air circulation and sunlight penetration while providing secure containment

Its open design facilitates air circulation and sunlight penetration while providing secure containment Its open design facilitates air circulation and sunlight penetration while providing secure containment galvanized welded wire mesh. The zinc coating ensures that the mesh remains resilient against weathering and animal damage.

galvanized welded wire mesh. The zinc coating ensures that the mesh remains resilient against weathering and animal damage.Galvanized iron wire finds extensive use in various industrial settings, where its durability, strength, and corrosion resistance make it invaluable for a range of applications. One of the primary industrial uses of this wire is in binding and baling materials such as cardboard, textiles, and waste products. The wire's robustness ensures that bundled materials remain securely bound during handling, transportation, and storage, contributing to the efficiency and safety of industrial operations.

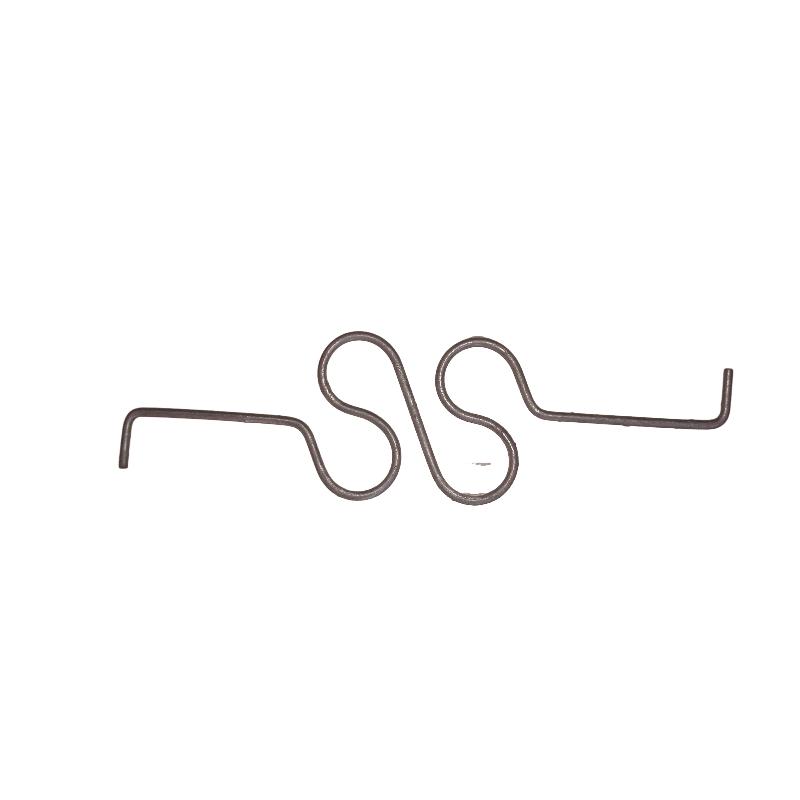

Extend the service life of the wall: A good connection can reduce the deformation and damage of the wall, thereby extending the service life of the entire cavity wall structure.

Engineers and architects often collaborate to determine the most appropriate anchor design, ensuring compliance with local building codes and standards Engineers and architects often collaborate to determine the most appropriate anchor design, ensuring compliance with local building codes and standards

Engineers and architects often collaborate to determine the most appropriate anchor design, ensuring compliance with local building codes and standards Engineers and architects often collaborate to determine the most appropriate anchor design, ensuring compliance with local building codes and standards masonry veneer anchor.

masonry veneer anchor. A spring of this particular size can be engineered to exert a specific amount of force, known as its spring rate A spring of this particular size can be engineered to exert a specific amount of force, known as its spring rate

A spring of this particular size can be engineered to exert a specific amount of force, known as its spring rate A spring of this particular size can be engineered to exert a specific amount of force, known as its spring rate 3 inch compression spring. This rate is measured in pounds per inch (lb/in), indicating how much weight is needed to compress the spring one inch. In precise machinery, such as those found in scientific instruments or high-end audio equipment, the 3-inch compression spring's dimensions and spring rate are meticulously calculated to ensure optimal performance.

3 inch compression spring. This rate is measured in pounds per inch (lb/in), indicating how much weight is needed to compress the spring one inch. In precise machinery, such as those found in scientific instruments or high-end audio equipment, the 3-inch compression spring's dimensions and spring rate are meticulously calculated to ensure optimal performance.

Cavity tie replacement

Galvanized annealed wire, on the other hand, is coated with a layer of zinc that provides excellent protection against rust and corrosion, making it ideal for construction, fencing, and agricultural applications.