Construction Sector

Construction Sector

Meeting Diverse Industry Needs

Calculating the Mud Pump An Essential Process in Drilling Operations

3. Customization Options Chinese manufacturers are increasingly able to provide customized solutions to meet specific industry or operational needs. This flexibility can be particularly beneficial for businesses with unique requirements.

2. Correct Configuration Ensuring that the jaw plates are correctly aligned and configured can prevent unnecessary wear and improve the overall crushing performance.

1. Earth Drilling Bullet teeth are ideal for drilling through dense and rocky soils. Their robust design allows operators to bore holes for foundations, utility poles, and other structures without compromising efficiency.

สรุป

What is a Fractional Head Hammer?

Inspection Before Using the Integrated Drilling and Piling Machine:

3. Open-air drilling rig: according to the different working mechanism of crushing ore and rock, it is divided into steel rope percussion drill, drilling rig, cone drill and rotary drill. Because of low efficiency, the steel rope percussion drill has been gradually replaced by other drilling RIGS. The drill pipe drives the pneumatic impactor and the drill bit to rotate together, and the piston of the pneumatic impactor is used to impact the drill bit to break the ore and rock, which is usually used in small and medium-sized mines to drill holes with a diameter of 80 to 250 mm.

Drivers might notice a whining or groaning noise when turning the steering wheel, a loss of power steering assistance, or even a puddle of fluid beneath the parked vehicle Drivers might notice a whining or groaning noise when turning the steering wheel, a loss of power steering assistance, or even a puddle of fluid beneath the parked vehicle

Drivers might notice a whining or groaning noise when turning the steering wheel, a loss of power steering assistance, or even a puddle of fluid beneath the parked vehicle Drivers might notice a whining or groaning noise when turning the steering wheel, a loss of power steering assistance, or even a puddle of fluid beneath the parked vehicle 3a713 power steering hose. Any of these symptoms should prompt an immediate inspection, as a faulty hose can lead to increased steering effort, compromising driver control and potentially posing a safety risk.

3a713 power steering hose. Any of these symptoms should prompt an immediate inspection, as a faulty hose can lead to increased steering effort, compromising driver control and potentially posing a safety risk. dodge avenger power steering hose. The mechanic will first diagnose the issue by checking for leaks and monitoring the hydraulic pressure. Once the problem is identified, they will remove the old hose and install a new one, ensuring a tight seal and proper fit.

dodge avenger power steering hose. The mechanic will first diagnose the issue by checking for leaks and monitoring the hydraulic pressure. Once the problem is identified, they will remove the old hose and install a new one, ensuring a tight seal and proper fit. 3 4 inch water pipe connector. Professional plumbers often use specialized tools to tighten and align them, ensuring airtight connections. Regular maintenance and inspection are also vital to prevent any potential issues like rusting, loosening, or wear and tear.

3 4 inch water pipe connector. Professional plumbers often use specialized tools to tighten and align them, ensuring airtight connections. Regular maintenance and inspection are also vital to prevent any potential issues like rusting, loosening, or wear and tear.

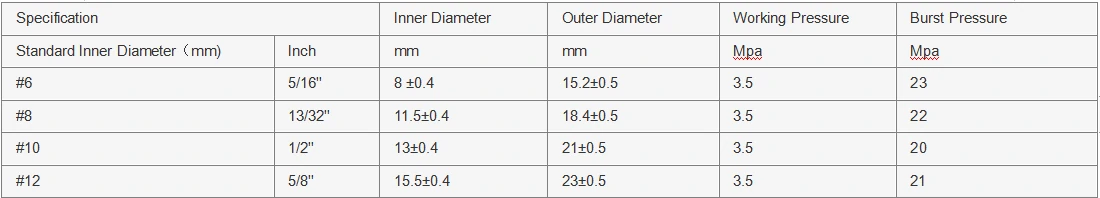

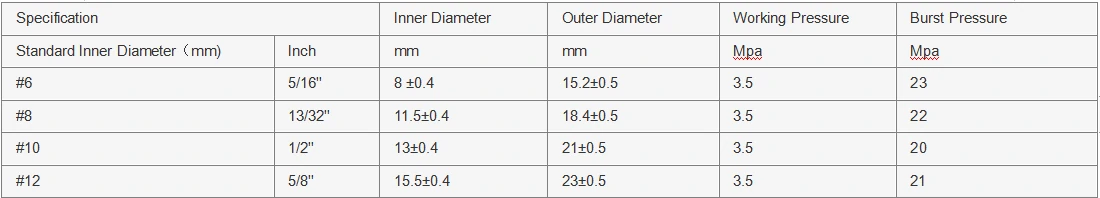

The diagram may also include details about the specific diameter and length of each hose, which are crucial parameters for ensuring the proper functioning of the system The diagram may also include details about the specific diameter and length of each hose, which are crucial parameters for ensuring the proper functioning of the system

The diagram may also include details about the specific diameter and length of each hose, which are crucial parameters for ensuring the proper functioning of the system The diagram may also include details about the specific diameter and length of each hose, which are crucial parameters for ensuring the proper functioning of the system ford 6.0 power steering hose diagram.

ford 6.0 power steering hose diagram.