perfuração martelo.

- الصناعات الثقيلة تلعب دورًا رئيسيًا في عمليات التصنيع، حيث تستخدم في تشغيل الآلات وتغدية سلسلة الإنتاج.

Challenges and Innovations

There are several types of pumps commonly used for handling slurry, each with its own advantages and limitations

3. Wastewater Management In the municipal sector, heavy slurry pumps are employed in wastewater treatment plants to manage the thick sludge produced during the breakdown of waste. Their ability to handle viscous materials makes them indispensable in ensuring that the treatment process is efficient and effective.

1. Efficiency DTH hammers are known for their speed. They can drill faster than conventional methods, which leads to reduced operational time and lower costs. The high impact energy translates to deeper penetration and the ability to tackle tougher materials.

When the pile driver is working, the pile driver should be reliably grounded to reduce the risk of personal electric shock.

1. Earth Drilling Bullet teeth are ideal for drilling through dense and rocky soils. Their robust design allows operators to bore holes for foundations, utility poles, and other structures without compromising efficiency.

- Cost-effectiveness Although bullet teeth may have a higher initial cost, their durability and long service life reduce overall replacement and maintenance expenses.

What are Self-Priming Slurry Pump Solutions?

What are Self-Priming Slurry Pump Solutions?

.

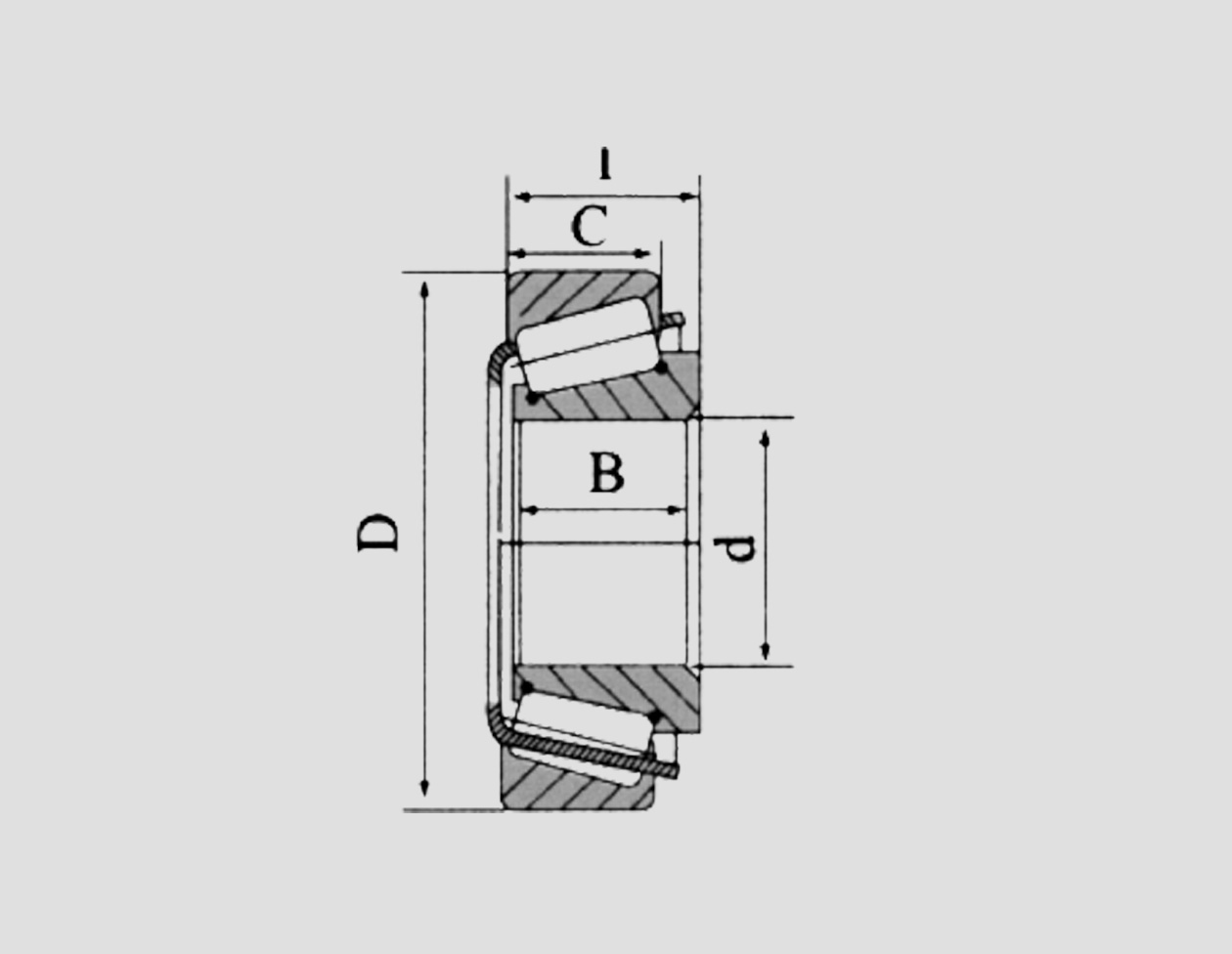

. However, without proper lubrication, bearings can quickly degrade, leading to costly downtime and reduced productivity However, without proper lubrication, bearings can quickly degrade, leading to costly downtime and reduced productivity

However, without proper lubrication, bearings can quickly degrade, leading to costly downtime and reduced productivity However, without proper lubrication, bearings can quickly degrade, leading to costly downtime and reduced productivity It is also commonly coated or treated with specialized lubricants to minimize friction, reduce heat generation, and prolong service life It is also commonly coated or treated with specialized lubricants to minimize friction, reduce heat generation, and prolong service life

It is also commonly coated or treated with specialized lubricants to minimize friction, reduce heat generation, and prolong service life It is also commonly coated or treated with specialized lubricants to minimize friction, reduce heat generation, and prolong service life

Aerospace components such as turbines and engines also rely on 592A bearings for their smooth operation Aerospace components such as turbines and engines also rely on 592A bearings for their smooth operation

Aerospace components such as turbines and engines also rely on 592A bearings for their smooth operation Aerospace components such as turbines and engines also rely on 592A bearings for their smooth operation