Наземные буровые установки

.

The reliability of gravel pumps directly impacts various industrial processes. Any downtime due to equipment failure can result in significant financial losses and delays in project timelines. Therefore, the reputation of a manufacturer often hinges on the quality and durability of their pumps. Companies that choose to partner with established manufacturers known for their rigorous quality control processes tend to experience fewer operational issues and enjoy better overall performance from their equipment.

Future Developments and Innovations

In addition to their durability, rubber-lined pumps are also designed for flexibility and efficiency. They can be customized to suit specific applications, with various types of rubber available to cater to different chemical resistances and temperature ranges. This adaptability makes them a popular choice across numerous sectors, from food processing to petroleum refining.

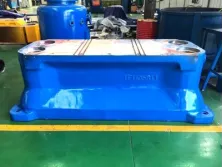

rubber lined pump

2. Automotive The automotive industry relies on spiral drill bits for precision drilling in engine components and bodywork. The rigorous requirements of this field necessitate tools that can deliver accuracy and durability.

- Cooling and Lubrication As drill bits generate heat, drilling fluids help in cooling and reducing friction.

Manufacturing Sector

Manufacturing Sector