compresor de aire cfm 185

DTH hammer drilling is widely utilized in various sectors, including

4. The average flow rate of the pipeline is too low, and the average flow rate of the pipeline is lower than the critical settlement deceleration, resulting in pipeline blockage and unable to transport slurry normally. Through the above examples, it can be seen that the selection of ZJ series slurry pump is more complicated, and if any link makes a mistake, it may lead to the mistake of the entire selection, causing irreparable losses to users, and having an adverse impact on their reputation. Therefore, in the selection, we must pay attention to the values of several key coefficients and calculate them carefully to achieve accuracy, so that the ZJ series slurry pump can fully reflect its advantages in field application.

Understanding Directed Drilling Rods

유지보수 및 관리

The production of rubber slurry pumps begins with the selection of high-quality materials. The primary components of these pumps include the pump casing, impeller, and wear components, all of which are crucial for efficient performance. Rubber, due to its excellent resilience and wear resistance, is widely used in constructing these components. Factories often source synthetic rubber, such as polyurethane, to enhance durability further, especially in harsh operating conditions.

Mining Industry

Mining Industry

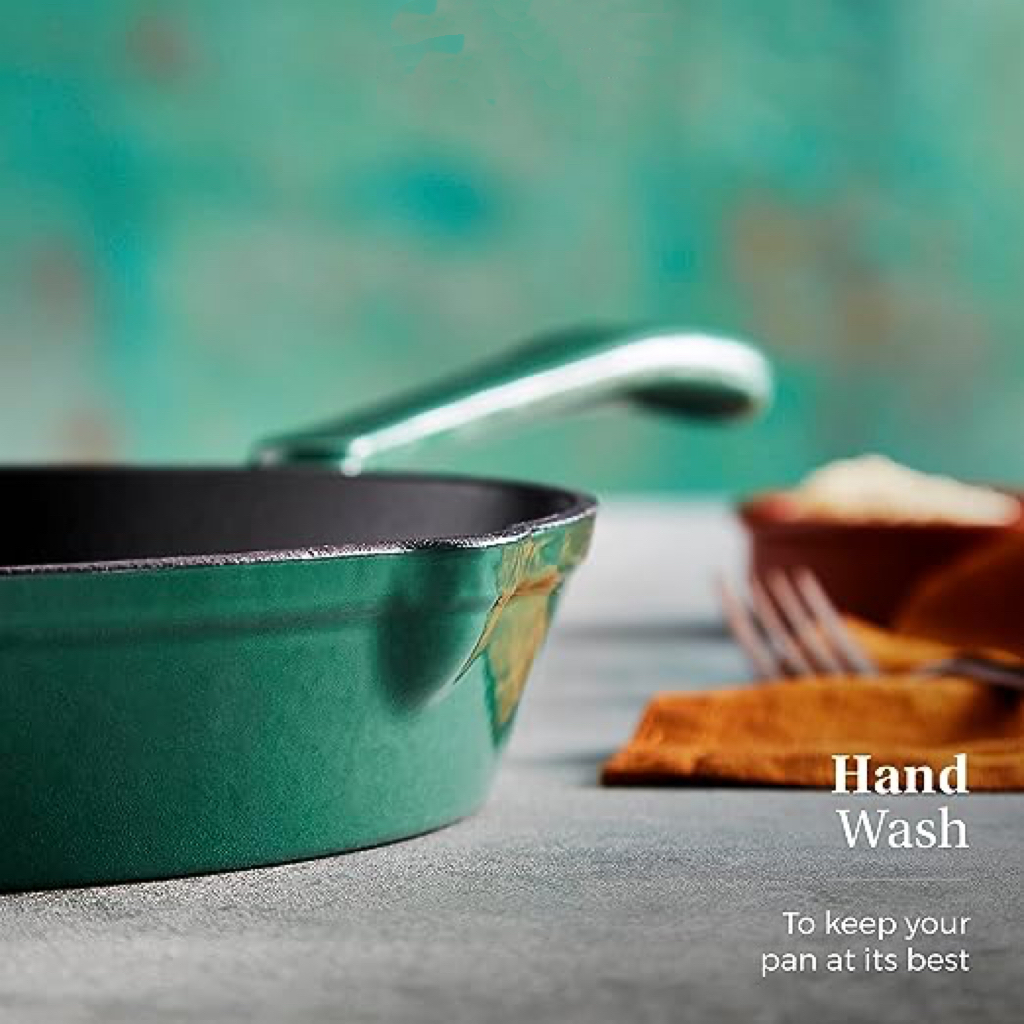

The flat surface also makes it easier to manage multiple dishes simultaneously, making it perfect for family gatherings or backyard barbecues The flat surface also makes it easier to manage multiple dishes simultaneously, making it perfect for family gatherings or backyard barbecues

The flat surface also makes it easier to manage multiple dishes simultaneously, making it perfect for family gatherings or backyard barbecues The flat surface also makes it easier to manage multiple dishes simultaneously, making it perfect for family gatherings or backyard barbecues