cabeça de martelo.

DTH hammer drilling is widely utilized in various sectors, including

The main components of submarine hammer drilling equipment include the drill rig, hammer, drill pipes, and the drill bit. The drill rig is often mounted on a surface vessel or a floating platform and is designed to support the excessive weight and dynamic forces encountered during drilling operations.

Before each day's operation, refill the 29 grease points with grease.

Moreover, the competitive landscape of the drilling equipment market has intensified due to the entry of new players and the globalization of supply chains. Manufacturers are now competing not just on price but also on technology and service quality. The collaboration between equipment manufacturers and end-users is becoming more prevalent, resulting in tailored solutions that address specific operational challenges.

In today’s rapidly evolving industrial landscape, the demand for drilling equipment has surged significantly. This growth can be attributed to a combination of factors, including advancements in technology, increased exploration activities, and the ongoing need for infrastructure development across various sectors. As industries continue to thrive, the sale of drilling equipment has become a vital focal point for manufacturers, suppliers, and end-users alike.

- Compressor A high-capacity air compressor supplies the necessary airflow to operate the percussion hammer and clear debris from the borehole.

Производитель грязных насосов Бизнес и технологии в Кыргызстане

When the pile driver is working, the pile driver should be reliably grounded to reduce the risk of personal electric shock.

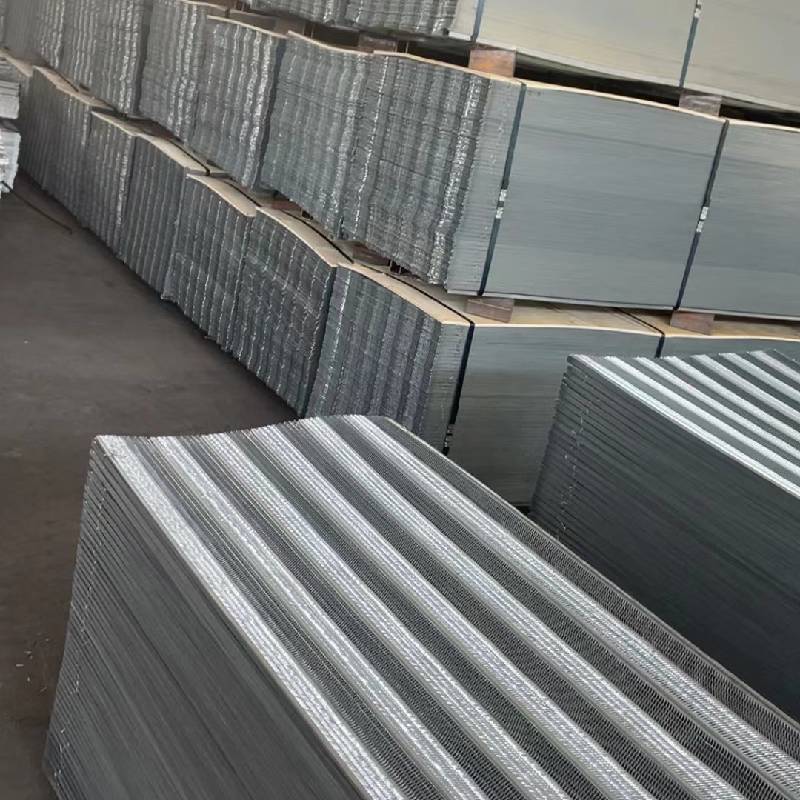

It's commonly used to construct livestock pens, trellises for vines, and even in the making of hay bales It's commonly used to construct livestock pens, trellises for vines, and even in the making of hay bales

It's commonly used to construct livestock pens, trellises for vines, and even in the making of hay bales It's commonly used to construct livestock pens, trellises for vines, and even in the making of hay bales

A well-placed, intricately designed support can act as a focal point, drawing the eye and guiding the viewer's journey through the garden A well-placed, intricately designed support can act as a focal point, drawing the eye and guiding the viewer's journey through the garden

A well-placed, intricately designed support can act as a focal point, drawing the eye and guiding the viewer's journey through the garden A well-placed, intricately designed support can act as a focal point, drawing the eye and guiding the viewer's journey through the garden Its open design facilitates air circulation and sunlight penetration while providing secure containment Its open design facilitates air circulation and sunlight penetration while providing secure containment

Its open design facilitates air circulation and sunlight penetration while providing secure containment Its open design facilitates air circulation and sunlight penetration while providing secure containment

We also have a range of heat-treated and non-heat-treated springs, each with its own unique properties and performance benefits We also have a range of heat-treated and non-heat-treated springs, each with its own unique properties and performance benefits

We also have a range of heat-treated and non-heat-treated springs, each with its own unique properties and performance benefits We also have a range of heat-treated and non-heat-treated springs, each with its own unique properties and performance benefits